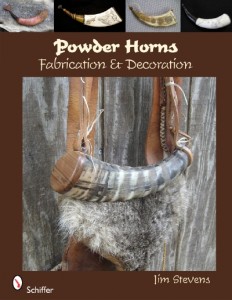

“Powder Horns: Fabrication & Decoration” a book review

Jim Stevens is a member of the Honourable Company of Horners and an author. Stevens wrote Powder Horns: Fabrication & Decoration. I asked Stevens if I could review the book and he sent me a loaner copy very quickly. My assessment of the book follows and I hope you enjoy it. By the way, the HCH’s publication, The Horn Book, will have a more detailed article about Jim Stevens in the next issue. Thanks for reading, Rick Sheets HCH Webmaster

Powder Horns: Fabrication & Decoration

Author: Jim Stevens

Schiffer Publishing

Size: 8 1/2″ x 11″

Illustrations: 275 color photos

Pages: 176

Binding: Soft Cover

First of all, I want to thank Jim Stevens for allowing me to review his book.

The book is thoughtfully laid out in six chapters, from horn basics through how to strap the horn for carrying. You can start with a fresh horn or hull, learn to turn it into a powder horn, embellish it and then finish with a finger woven strap. Stevens’ book does not gloss over anything.

Something I look for in a “how to” book is appropriate illustrations or photographs. Stevens’ book has 275 of them. Stevens’ writing is clear and concise. He picked a clean, modern type face and size that makes the book easy to read.

Chapter 4 was most interesting for me. Stevens takes the reader through the decorating process. Stevens illustrates the time-tested scrimshaw techniques for the purist.

And then how to use technology to help get the image you want on your horn. The option of using modern transfer techniques is very nice if you have a complex image to reproduce or if you are challenged in drawing. So do it old-school or new-school; it is up to you.

I would like to point out that the book has what I consider a bonus; you will find a whole chapter on how to weave a strap using several different methods. Using the clear instructions in this book removes any excuse you have for making a nice horn and then strapping it badly!

After reading Powder Horns: Fabrication & Decoration, I can truthfully say, “Pick-up the book, then buy your horn and tools.” You will save a few false starts and a wasted horn or two.

>>Buy the book from Schiffer Publications from this link.<<

-Rick Sheets

Powder Horns: Fabrication & Decoration

Author: Jim Stevens

Schiffer Publishing

Size: 8 1/2″ x 11″

Illustrations: 275 color photos

Pages: 176

Binding: Soft Cover

First of all, I want to thank Jim Stevens for allowing me to review his book.

The book is thoughtfully laid out in six chapters, from horn basics through how to strap the horn for carrying. You can start with a fresh horn or hull, learn to turn it into a powder horn, embellish it and then finish with a finger woven strap. Stevens’ book does not gloss over anything.

Something I look for in a “how to” book is appropriate illustrations or photographs. Stevens’ book has 275 of them. Stevens’ writing is clear and concise. He picked a clean, modern type face and size that makes the book easy to read.

Chapter 4 was most interesting for me. Stevens takes the reader through the decorating process. Stevens illustrates the time-tested scrimshaw techniques for the purist.

And then how to use technology to help get the image you want on your horn. The option of using modern transfer techniques is very nice if you have a complex image to reproduce or if you are challenged in drawing. So do it old-school or new-school; it is up to you.

I would like to point out that the book has what I consider a bonus; you will find a whole chapter on how to weave a strap using several different methods. Using the clear instructions in this book removes any excuse you have for making a nice horn and then strapping it badly!

After reading Powder Horns: Fabrication & Decoration, I can truthfully say, “Pick-up the book, then buy your horn and tools.” You will save a few false starts and a wasted horn or two.

>>Buy the book from Schiffer Publications from this link.<<

-Rick Sheets

PS: Please note that Jim Stevens will be giving: Scrimshaw Instruction June 6 – June 10, 2011 at The NRA Gunsmithing School Trinidad State Junior College (Trinidad, CO) Follow this link for more information. www.scrimshawstudio.com/tsjc.html

Search for the Ackley Horn

We had an unusual request from Mark Ackley, who is a family historian. He needs help to find an heirloom that was sold at auction. The details of the powder horn in question are sketchy and the only known photographs of the horn are not the best. What we can see is a nice, right side horn with a cityscape engraving at the top. The horn has little twist and the low dome butt is held with domed tacks. There is additional engraving on the horn, but one cannot tell much from the photos. If you know the whereabouts of this horn, please use the form below. Regards, Rick Sheets HCH Webmaster

If you know where this horn is, please use the form below.

If you know where this horn is, please use the form below.

The Spring Pole Lathe Project – Update March 12, 2011 – Nearing Completion

Left to right. Ed Long, Guildmaster, Dick Toone, lathe builder and Rowland Cadle, Master Horner and Founder.

Dick Toone, project leader of the spring pole lathe project, displayed the lathe at the HCH’s Fifteenth Annual Meeting at Fort Roberdeau. It was very close to completion. Once it is complete the lathe will enable the user to turn all of the parts for a screw-tip horn using only human power much the way it was done in the 18th and the early 19th Centuries.

Dick Toone is sawing out the slot for the boom to pivot on with best tool for the job, an original bow saw.

Temporary Mandrel

Here is the the temporary mandrel (with the rope around it) supported on a fixed center point at right and the bearing end in a temporary support of wood. When finished the mandrel will be made with a short piece of octagonal rifle barrel with a brass bearing on the end to the left and a wooden spool where the rope will turn it. The rifle barrel end protruding from the bearing will have coarse external threads that various fixtures (face plates) will thread on to to hold screw tip horn parts for turning. Also shown is a mandrel with a fixed drill bit installed made by Erv Tschanz. Several fixed tool mandrels will be employed to do various functions in the manufacture of a screw tip horn.

The next installment will show the finished Portable 18th Century Spring Pole Lathe.

By the way, I urge you to go to Dick Toone’s website, Living History Shop, to view his museum quality 18th Century reproductions.

Regards, Rick Sheets HCH Webmaster

Col. Carl Dumke, USAF an Emerging Horner

Carl Dumke does take on commissions for trade signs on occasion. You may reach him through his email address, which is cdumke99@aol.com.The Jonathan Bagley Horn (by Carl Dumke) Dumke identifies with Col. Bagley and wanted to make a horn to honor Bagley’s engagement against the Iroquois and French at Fort William Henry. Here is a series of photos of a campaign horn in period style inspired by the horner John Bush. (The pictures are lightened to show the detail of the horn.)

Recent Comments