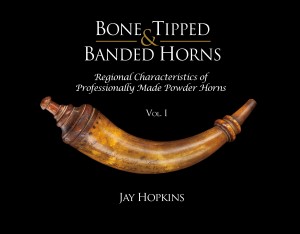

Shipping Books NOW! Bone Tipped & Banded Horns Regional Characteristics of Professionally Made Powder Horns

Bone Tipped & Banded Horns

Bone Tipped & Banded Horns

Regional Characteristics of Professionally Made Powder Horns

By Jay Hopkins

Published by The Honourable Company of Horners

For any student of powder horns and or the Kentucky rifle, this is a “must have book” for your personal library.

This first volume of a planned two volume set is the culmination of a 50-year study concentrating on regional characteristics of professionally made powder horns. It has been significantly augmented by collaboration and cooperation with other collectors, students and museums. The focus is on powder horns of the south including Virginia, North Carolina, West Virginia, Tennessee, Kentucky, Georgia, but also includes examples from South Carolina, Alabama, Mississippi, Louisiana, Texas, Missouri, Illinois, Indiana, Ohio, Pennsylvania, New York and New England.

Volume 1 is hardbound with approximately 400 pages, over 150 powder horns illustrated and over 700 full color images. Each horn will be illustrated, measured in multiple parameters and the various materials and woods are identified. Then, pertinent history and biographical information will be included, as well as an analysis of the horn and its likely origin. This study will provide an excellent framework for future study and clarification.

$100.00, plus $10.00 postage.

Payment by cash, check or money order, made to “HCH”:

510 Coffin Alley, PO Box 382

Portland, PA 18351

The HCH Spring Pole Lathe Project Update – November 2015

Guildmaster Dick Toone is the designer and maker (and demonstrator!) of the Guild’s spring pole lathe. The lathe is adapted with purpose built attachments for making powder horn parts. Dick is also the artisan behind The Living History Shop (www.livinghistoryshop.com) where this posting first appeared. It is reproduced here to serve as an update to the project.

In 2011 I undertook the Honourable Company of Horners’ By-Law project that provides the Guild have an 18th Century traveling horn shop for educational demonstration at various  guild related or historical presentations. The lathe is specific to the production of professionally made powder horns using lathe construction detail of an original example capable of turning in open air without fixed centers. A very rare example of this sort of lathe exists in the collections of Old Salem, Winston-Salem, North Carolina.

guild related or historical presentations. The lathe is specific to the production of professionally made powder horns using lathe construction detail of an original example capable of turning in open air without fixed centers. A very rare example of this sort of lathe exists in the collections of Old Salem, Winston-Salem, North Carolina.

Old Salem gave me permission to photograph and measure the original and a full size reproduction made by resident gunsmith Blake Stevenson operating in “The Brothers House” original structure. Old Salem is similar to Colonial Williamsburg other than it is in all original buildings, has working gunsmiths and bread baked in a 250 year old oven. Old Salem should be on every historical enthusiast’s bucket list. (www.oldsalem.org)

Spring Pole lathes were state of the art for about 500 years gradually replaced by large wheel belt driving small wheel lathes using an off-set crank on the large wheel operated by direct coupling to foot driven rocker treadle toward the end of the 1700′s. These later lathes are called treadle lathes (direct continuous drive) even though a treadle board operated spring pole lathes for centuries.

A major part of the lathe challenge was to establish means to hold and turn things with only known to the period devices. This required jigs, fixtures and even tools unique to the operation of a slow turning lathe that only operates one and one-half turn towards the operator per stroke of the foot.

Modern lathes have easily adjustable inner and outer chucks not available in spring pole times. Professionally made powder horns from a Horn Shop would have been constructed of turned components that could be closely fitted round to round for sealing out moisture. “Keep your powder dry!,” as the saying goes.

Professional Horn Shops made various tight containers, combs, buttons, shoe horns, rims for optical lenses(glasses), drinking tumblers and window pane. Yes, flat clear pane for horn books used in schools as well as lanthorns, later called lanterns with glass or mica lenses. When heated cattle horn becomes plastic an adjective meaning malleable. Modern plastic is used as a noun for polymerized, chemical stew that replaced thousands of laborers in the horn industry early last century.

The epicenter of American horn manufacturing was in Philadelphia in the 18th Century boasting twelve shops at the time between the French and Indian war and the American Revolution. Horn smiths looking to strike out on their own relocated to the Southern and Western frontiers producing styles of horn independent of Philadelphia styling allowing researchers today to regionalize examples to a county and sometimes a town by their unique design. The hornsmiths migrated to wherever the frontier moved and the need existed.

Common to almost all professionally made powder horns is a stylized round wooden plug sealed tightly to the heated rounded horn at the big end opening. The tip of the horn is cut off and threaded of a size more suitable for refilling the powder horn. A two to three inch horn tip with a smaller diameter hole is tightly threaded into the main horn. Optimum word tightly to seal. Around the threaded portion of the horn body a horn collar is turned and fitted to provide structural strength to the area around the threaded portion. All of these items need a lathe to make them expertly and each item requires fixtures designed to work within the scope of 18th Century machining. This is experimental archaeology and none of the horns I’ve made are for sale.

Check out www.hornguild.com for more education about working in cattle horn and this link to see a number of “posts” about the Honourable Company of Horners’ spring pole lathe project.

I will be demonstrating with the Spring Pole Lathe at Horn Guild annual convention in March of 2016, Dixon’s Gun Fair in Kempton, PA and the CLA show in August at Lexington, KY in 2016. I will be demonstrating the lathe local to me at the Jersey History Fair at Monmouth Battle Park Freehold, NJ in May 2016.

Regards,

Dick Toone

Guild Supports a Project at the Jacobsburg Historical Society

11 Year Old Tristan Frigm files a horn at Jacobsburg. Photo: Dave Ehrig

Scott Morrison at the 2010 HCH Dinner at Jacobsburg. |

The Barn Complex at Jacobsburg. |

Recent Comments